Manufacturing & Process Engineer New Delhi (Remote) · Hybrid

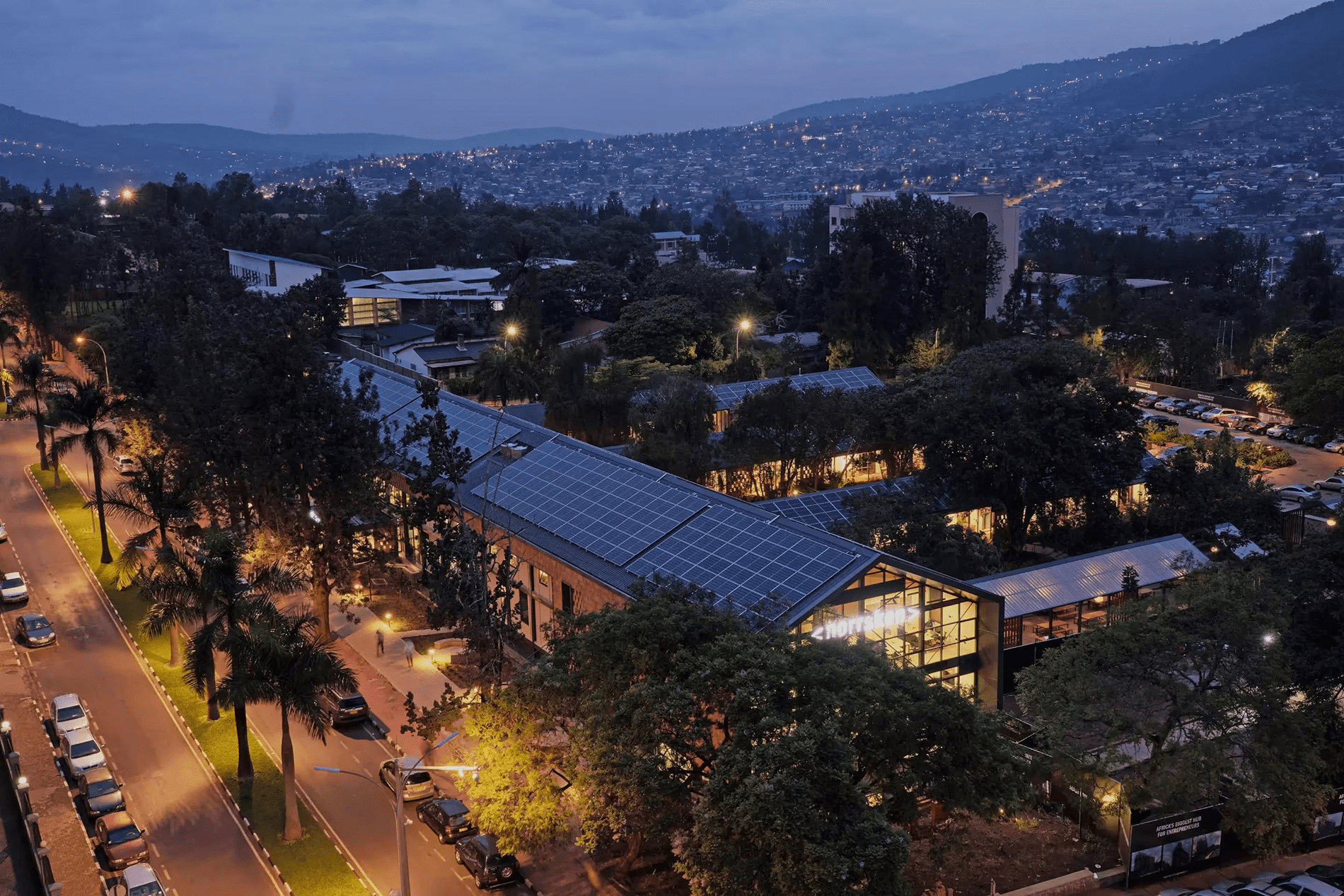

Submer - Datacenters That Make Sense

Manufacturing & Process Engineer

Location & work modality: Delhi (remote)

Start: ASAP

Type of Contract: Full Time

Travel Requirements: 30%

About Submer

At Submer, we are redefining how data centers are built, integrated, and operated, with sustainability, efficiency, and innovation at the core. Our technology is designed to reduce environmental impact while improving performance and efficiency. We are a purpose-driven company with a passion for innovation and a growing global presence.

What impact you will have

As a Manufacturing & Process Engineer, you will play a crucial role in ensuring that both internal and external manufacturing processes operate at maximum efficiency. You will support suppliers, qualify and improve their processes, and work closely with engineering, quality, and supply chain teams to industrialize products reliably and cost-effectively.

Your work will directly influence product quality, production speed, manufacturing cost, and the overall scalability of the product lifecycle. You will be the technical reference for production methods, process capability, and continuous improvement initiatives across the supply chain.

What you’ll do

You will be involved in:

Supplier Industrialization & Support

• Evaluate, qualify, and continuously improve supplier manufacturing processes.

• Conduct supplier process audits, capability studies, and risk assessments (PFMEA).

• Support suppliers during ramp-ups, new line deployments, and introduction of new components.

• Lead root-cause analysis and drive corrective actions for supplier-related issues.

Internal Manufacturing Processes

• Define, document, and optimize internal production processes to maximize efficiency, safety, and quality.

• Create standard work instructions, process flow diagrams, and layout optimization proposals.

• Implement Lean, 6-Sigma, and continuous improvement tools (VSM, Kaizen, 5S, SPC).

• Support production teams in reducing waste, increasing throughput, and solving day-to-day process deviations.

New Product Industrialization (NPI)

• Collaborate with design engineering to ensure manufacturability (DfM/DfA).

• Support prototype builds, pilot runs, and transition to volume production.

• Define process control strategies, testing requirements, and acceptance criteria.

• Build and maintain process validation documentation.

Process Control

• Define and track supplier and internal manufacturing KPIs.

• Create and monitor control plans and process capability studies.

• Lead investigations when deviations occur and implement robust, data-driven improvements.

• Ensure compliance with applicable safety and quality standards.

Cross-Functional Collaboration

• Work closely with Procurement, Quality, Engineering, Planning, and Installation teams.

• Ensure alignment between product design, process capability, and supply chain needs.

• Provide technical support to the Assembly Facility when scaling operations.

What you’ll need

5+ years in manufacturing/process engineering or industrialization roles (industrial or electromechanical sectors preferred).

• Strong experience working directly with suppliers and external manufacturing partners.

• Proven experience implementing Lean/6-Sigma/continuous improvement methodologies.

• Hands-on experience with metal, electrical, and mechanical manufacturing processes.

• Experience conducting PFMEA, VSM, SPC, and process capability studies (Cp, Cpk).

• Demonstrated ability to introduce new production lines, qualify processes, or scale up manufacturing.

• Deep understanding of manufacturing processes, production flows, and process control systems.

• Skilled in reading engineering drawings, tolerances, and technical specifications.

• Knowledge of testing methods, quality tools, statistical analysis, and root-cause methodologies

• ERP & data-driven mindset: comfortable using data for decision making and performance tracking.

Soft Skills

• Strong analytical and problem-solving skills.

• Excellent communication with technical and non-technical stakeholders.

• Ability to manage multiple stakeholders and priorities.

• Proactive mindset, autonomy, and a continuous improvement attitude.

• Excellent English communications ability.

What we offer

Attractive compensation package reflecting your expertise and experience.

A great work environment characterised by friendliness, international diversity, flexibility, and a hybrid-friendly approach.

You´ll be part of a fast-growing scale-up with a mission to make a positive impact, offering an exciting career evolution.

Our Inclusive Responsibility

Submer is committed to creating a diverse and inclusive environment and is proud to be an equal opportunity employer. All qualified applicants will receive consideration for employment without regard to race, color, religion, gender, gender identity or expression, sexual orientation, national origin, genetics, disability, age, veteran status, or any other protected category under applicable law.

- Locations

- New Delhi (Remote)

- Remote status

- Hybrid

About Submer

From concept to deployment, we create liquid-cooled datacenters that scale smarter, run cleaner and cost less.

Manufacturing & Process Engineer

Already working at Submer?

Let’s recruit together and find your next colleague.